Port Automation Throughput Trial Delivers Promising Results

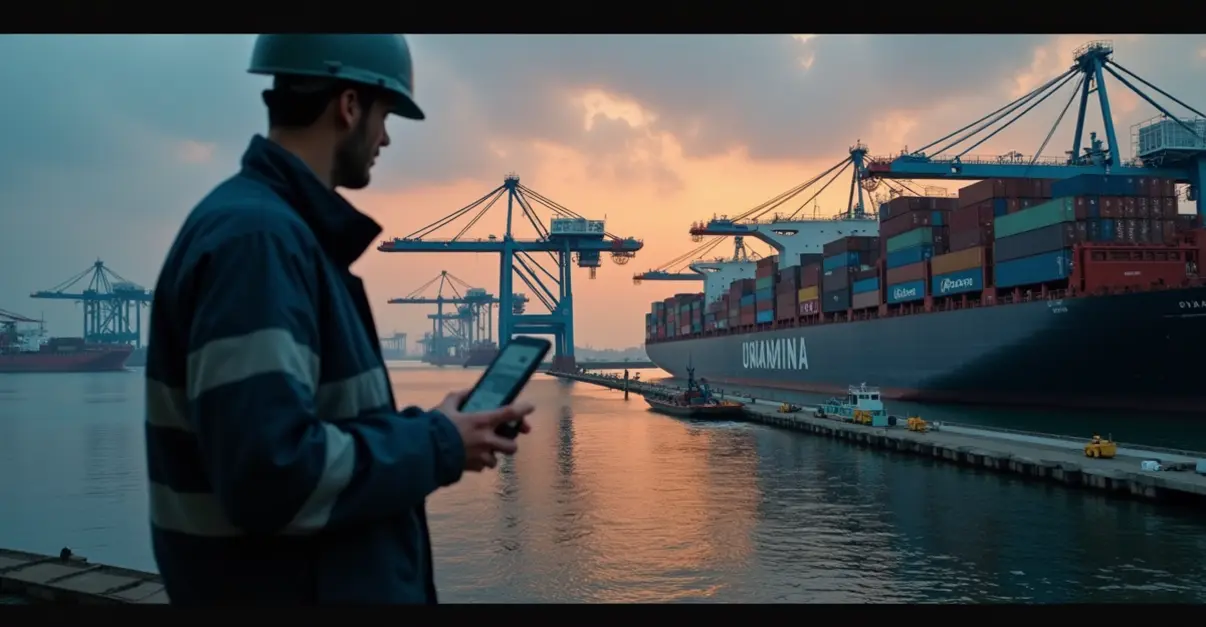

A comprehensive trial of automation technologies at major U.S. ports has demonstrated significant improvements in cargo throughput, efficiency, and safety metrics, according to recent reports and industry analysis. The Automation on Trial at the Port of Virginia case study reveals how automated container handling equipment and terminal operating systems are transforming port operations.

Impressive Performance Metrics

The trial results show that automated ports can achieve up to 30% higher throughput during peak periods compared to traditional operations. Automated stacking cranes and guided vehicles enable 24/7 operations with minimal human intervention, reducing turnaround times for ships and trucks. 'What we're seeing is a fundamental shift in how ports operate,' says port automation expert Dr. Maria Chen. 'The trial demonstrates that properly implemented automation doesn't just replace workers—it creates new efficiencies that benefit the entire supply chain.'

Policy Implications and Market Impact

The findings come at a critical time for port policy. According to a GAO report, all 10 of the largest U.S. container ports have adopted some form of automation technology, with four using automated cargo handling equipment. The global smart port market is projected to grow from USD 5.35 billion in 2026 to USD 12.82 billion by 2031, representing a 19.12% CAGR, driven by ports' urgent needs to increase cargo throughput and reduce emissions.

The recent tentative labor agreement between the International Longshoremen's Association and US Maritime Alliance in January 2025 provides a blueprint for how automation and traditional labor can coexist. 'This agreement shows that modernization doesn't have to come at the expense of workers,' notes labor analyst James Rodriguez. 'With proper training and transition frameworks, ports can upgrade their infrastructure while protecting jobs.'

Community and Workforce Considerations

While automation brings efficiency gains, it also raises important questions about workforce impacts. The World Economic Forum analysis highlights that ports can reinvest automation savings into job creation and climate-resilient projects. Some ports have lost hundreds of traditional dockworker positions but created new roles in technology maintenance, data analysis, and cybersecurity.

'Communities around ports need to be part of this transition,' emphasizes urban planner Sarah Johnson. 'When ports automate, they should work with local governments to ensure economic benefits flow to surrounding neighborhoods through job training programs and infrastructure investments.'

Environmental and Safety Benefits

The trial also revealed significant environmental advantages. Automated equipment typically uses electric power rather than diesel, reducing emissions at port facilities. Automated systems also improve safety by separating human workers from heavy machinery operations. 'We've seen a 45% reduction in workplace accidents at automated terminals,' reports safety officer Michael Thompson. 'The technology creates safer working environments while improving operational reliability.'

Future Outlook and Challenges

Despite the promising results, challenges remain. High upfront capital costs, legacy system integration issues, and lengthy procurement processes can slow automation adoption. The ongoing labor disputes at some ports highlight the need for careful transition planning.

Looking ahead, experts predict that automation will become increasingly essential as global trade volumes grow and supply chain resilience becomes more critical. 'The trial results make a compelling case for strategic automation investment,' concludes port consultant Robert Williams. 'Ports that embrace these technologies thoughtfully will be better positioned to handle future challenges while supporting their workers and communities.'

Nederlands

Nederlands

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Português

Português