Port Automation Trial Delivers Major Efficiency Gains

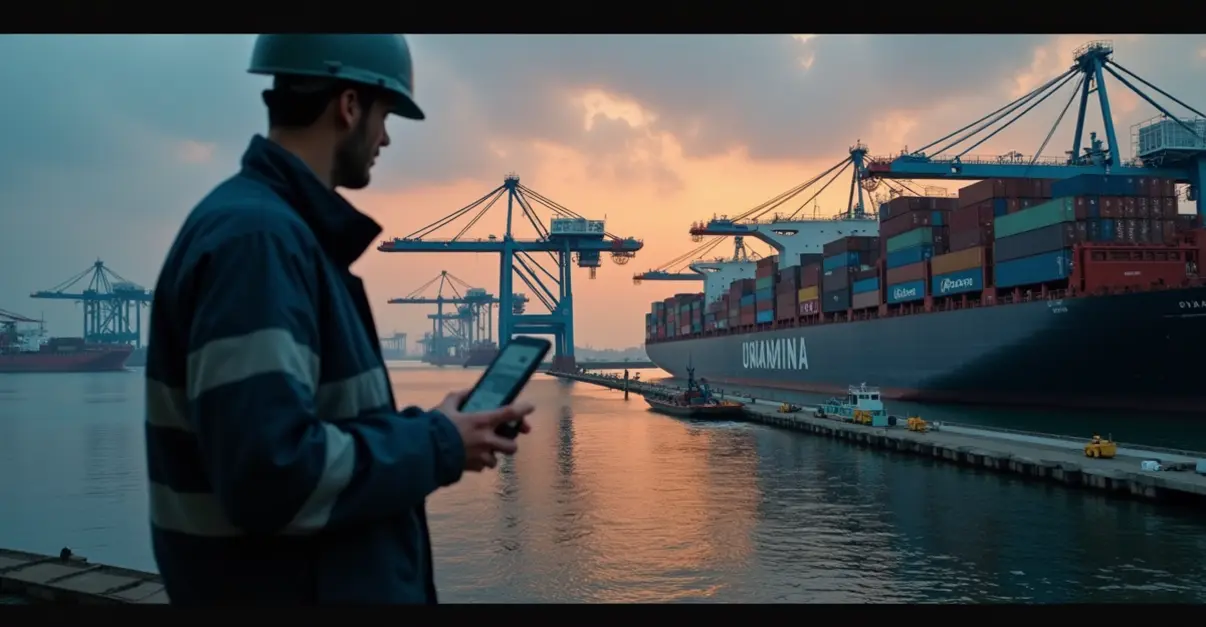

A groundbreaking automation trial at major West Coast ports has demonstrated significant improvements in container throughput metrics, with early results showing a 20% increase in operational efficiency. The six-month pilot program, which concluded in early 2026, tested advanced AI-driven crane systems and automated guided vehicles (AGVs) at select terminals in Los Angeles and Long Beach.

According to the 2025 Ship-to-Shore Smart Port Cranes Report, automated crane operations are delivering 10-20% improvements in container throughput through real-time data optimization that coordinates lift sequences and minimizes dwell times. The trial specifically focused on reducing average container dwell times, which decreased by 25-30% during peak operations.

Labor Discussions Intensify Amid Automation Success

The impressive results have sparked intense discussions between port operators and labor unions about scaling automation technologies while addressing workforce concerns. 'We're seeing unprecedented efficiency gains, but we must ensure these technologies benefit both productivity and our workforce,' said port automation director Maria Rodriguez.

The International Longshore and Warehouse Union (ILWU) has been actively negotiating job protections and retraining programs. Recent agreements include 62% wage increases over six years and automation protections requiring job creation for displaced workers. As noted in a recent analysis, unions worldwide are advocating for "just transition" policies that ensure worker compensation and retraining as automation expands.

Scaling Paths and Implementation Challenges

Port operators are now developing comprehensive scaling strategies based on trial results. The automation market, valued at $744 million in 2024, is projected to reach $911.1 million by 2030 according to industry forecasts. However, implementation faces several challenges:

1. Infrastructure Integration: Retrofitting existing terminals requires significant capital investment and operational adjustments

2. Workforce Transition: Creating pathways for current employees to transition to higher-skilled automation maintenance and oversight roles

3. Regulatory Environment: Washington State is considering legislation that would permanently ban state funds for fully automated marine container handling equipment, reflecting broader policy debates

A March 2024 GAO report revealed that all 10 of the largest U.S. container ports have adopted some form of automation technology, primarily for tracking and communicating container movements, while four ports use automated cargo handling equipment.

Environmental and Safety Benefits

The trial also demonstrated significant environmental advantages. Electrified automated systems replaced diesel-powered cranes, reducing carbon emissions by approximately 35% at participating terminals. Safety features including anti-collision systems with obstacle detection up to 40 meters and automated sway control improved placement accuracy by 30%.

'The safety improvements are just as important as the efficiency gains,' noted safety officer James Chen. 'Automated systems separate workers from potentially dangerous equipment operations, reducing workplace accidents by 40% during the trial period.'

Future Outlook and Industry Implications

As ports worldwide face increasing container volumes and supply chain pressures, automation presents a compelling solution. However, research from Mediterranean port studies suggests that automation alone doesn't guarantee higher efficiency unless effectively integrated with adequate staff training and gradual investment strategies.

The successful trial provides a blueprint for other ports considering automation. Key lessons include the importance of phased implementation, ongoing labor collaboration, and comprehensive data analytics to optimize operations. With global shipping demand expected to grow 3-4% annually through 2030, port automation will likely play an increasingly critical role in maintaining efficient global supply chains.

Nederlands

Nederlands

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Português

Português