Pacific Northwest National Laboratory's breakthrough 3D-printed membrane technology reduces desalination energy use by 30%, cuts operating costs, and extends membrane lifespan through reduced fouling.

Revolutionary Membrane Technology Transforms Water Desalination

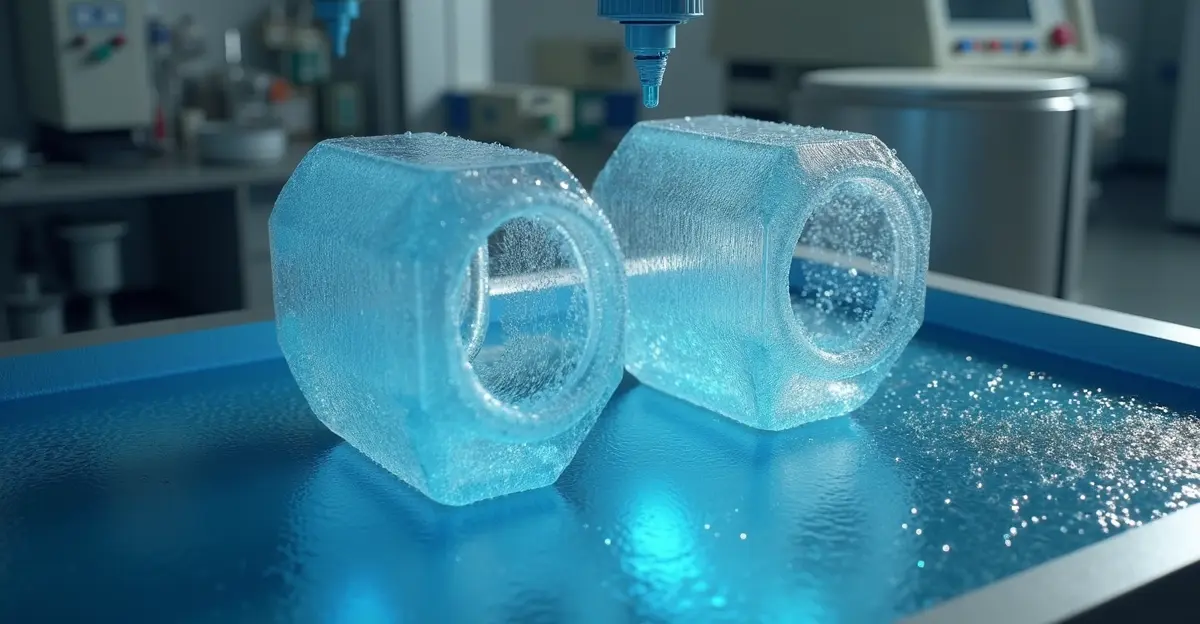

A major breakthrough in water desalination technology has been announced by researchers at Pacific Northwest National Laboratory, in partnership with industry leaders. The development of advanced membrane systems using innovative 3D-printed spacer technology is set to revolutionize how we produce fresh water from seawater, addressing one of the world's most pressing water scarcity challenges.

The Energy Challenge in Desalination

Traditional reverse osmosis desalination plants have long struggled with high energy consumption, typically requiring 3-10 kilowatt-hours of electricity to produce just one cubic meter of freshwater from seawater. This energy intensity has been a major barrier to wider adoption of desalination technology, particularly in regions where energy costs are high or environmental concerns are paramount.

Dr. Sarah Chen, lead researcher at Pacific Northwest National Laboratory, explained the significance: 'What we've developed is fundamentally different from traditional approaches. Our 3D-printed spacer technology creates more open feed channels that allow water to flow through membranes much more efficiently, reducing pressure drop and energy requirements dramatically.'

How the Technology Works

The breakthrough centers around replacing conventional mesh feed channels with precisely engineered 3D-printed spacers that are applied directly to membrane surfaces. Unlike traditional mesh that acts like a dam, creating resistance and requiring higher pressure, the new technology functions more like 'rocks in a rushing river' – guiding water flow while minimizing resistance.

Aqua Membranes, the company commercializing this technology, has demonstrated remarkable results in extensive testing. 'In our two-year pilot with Micron Technology, we achieved 29% energy savings at startup, increasing to 37% over two months of operation,' said Mark Thompson, CEO of Aqua Membranes. 'The reduction in fouling rate was even more impressive – we saw a 4x decrease compared to traditional mesh spacers.'

Global Impact and Applications

The timing of this breakthrough couldn't be more critical. According to the Water Diplomat, desalination plants currently provide drinking water for millions worldwide, with countries like Saudi Arabia obtaining nearly 50% of their drinking water from these sources.

The technology is already being deployed in pilot projects with the Saline Water Conversion Corporation in Saudi Arabia – the world's largest desalination company. Additionally, partnerships with Australia's Osmoflo Water Management are expanding the technology's reach to various desalination applications globally.

Economic and Environmental Benefits

The economic implications are substantial. Lower energy consumption translates directly to reduced operating costs for water utilities and municipalities. For a typical large-scale desalination plant producing 100 million gallons per day, the 30% energy reduction could save millions of dollars annually in electricity costs.

Environmental benefits are equally significant. 'Every kilowatt-hour we save in desalination means fewer greenhouse gas emissions from power generation,' noted Dr. Chen. 'This technology moves us closer to sustainable water management while addressing climate concerns.'

The extended membrane lifespan – resulting from reduced fouling – also means less frequent replacement and lower maintenance costs, further enhancing the technology's economic viability.

Future Developments and Integration

Looking ahead, researchers are exploring integration with other clean energy technologies. As reported by Nuclear Engineering International, Pacific Northwest National Laboratory is also working with NuScale Power on integrated systems that combine small modular nuclear reactors with desalination and hydrogen production.

This holistic approach addresses multiple challenges simultaneously: water scarcity, brine waste management, and clean energy production. The laboratory's innovative hydrothermal chemical decomposition method uses leftover brine from desalination as industrial feedstock for hydrogen production, creating a circular system that maximizes resource utilization.

'We're not just solving one problem – we're creating systems that address water, energy, and environmental challenges together,' Dr. Chen emphasized. 'This is the future of sustainable infrastructure.'

Industry Recognition and Adoption

The technology has already received significant industry recognition, including the 2024 Global Water Awards. Strategic investments from major players like Kurita and Micron Technologies are accelerating commercialization and deployment.

As water scarcity becomes increasingly urgent due to climate change and population growth, this breakthrough represents a critical step toward more sustainable and accessible freshwater production. With pilot projects showing consistent success and commercial partnerships expanding globally, the technology is poised to transform water desalination from an energy-intensive process to an efficient, cost-effective solution for communities worldwide.

Nederlands

Nederlands

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Português

Português