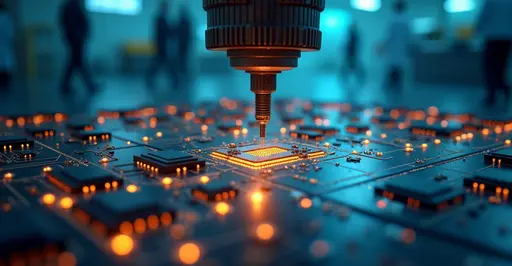

India's Semiconductor Expansion

India has approved its sixth semiconductor manufacturing facility, a joint venture between HCL and Foxconn near Uttar Pradesh's Jewar Airport. This move is part of the India Semiconductor Mission aiming to reduce dependence on imported chips. The plant will produce display driver chips for mobile devices, laptops, and automotive systems with a capacity of 20,000 wafers monthly.

Growing Manufacturing Ecosystem

Five additional semiconductor units are in advanced construction stages across India. Tata Electronics is building a fabrication plant in Dholera, Gujarat through a partnership with Taiwan's Powerchip Semiconductor Manufacturing Corporation (PSMC). Meanwhile, Micron Technology's assembly and testing facility in Sanand, Gujarat is expected to begin operations by early 2025. These projects represent investments exceeding $15 billion collectively.

Strategic Importance

Currently importing 65% of its electronics, India aims to capture 25% of the global semiconductor design market by 2029. The government is offering 50% subsidies on project costs through the Modified Semicon India Programme. "This positions India as a key player in the electronics supply chain," stated Union Minister Ashwini Vaishnaw.

Economic Impact

The semiconductor push could create over 100,000 skilled jobs by 2030. CG Power-Renesas' OSAT facility and Tata's Assam unit will further strengthen packaging capabilities. With the semiconductor market projected to reach $109 billion by 2030, India is also exploring next-generation 2D materials like graphene to leapfrog current technology limitations.

Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Español

Español Português

Português