Automotive Industry Faces Supply Chain Crunch

The automotive industry continues to grapple with significant supply chain disruptions, particularly in semiconductors and logistics. These challenges, which began during the COVID-19 pandemic, have persisted into 2025, causing delays in production and rising costs for manufacturers and consumers alike.

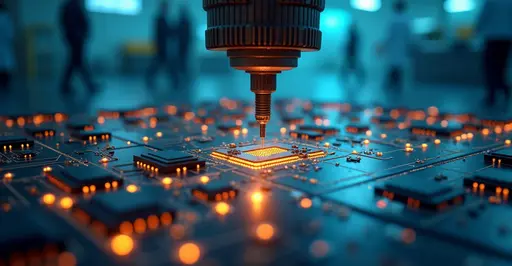

Semiconductor Shortages

The global shortage of semiconductors remains a critical issue for the automotive sector. These chips are essential for modern vehicles, powering everything from infotainment systems to advanced driver-assistance features. Despite efforts to ramp up production, demand continues to outstrip supply, leading to extended lead times and higher prices.

Logistics Bottlenecks

Logistics disruptions, including port congestion and shipping delays, have further exacerbated the supply chain crisis. The automotive industry relies heavily on just-in-time manufacturing, making it particularly vulnerable to these bottlenecks. Companies are now exploring alternative supply routes and increasing inventory buffers to mitigate risks.

Industry Response

Automakers and suppliers are collaborating to address these challenges. Initiatives include diversifying supply chains, investing in local production, and adopting digital tools for better visibility and coordination. However, experts warn that full recovery may take several more years.

Nederlands

Nederlands

English

English

French

French

Deutsch

Deutsch

Espaniol

Espaniol

Portugese

Portugese